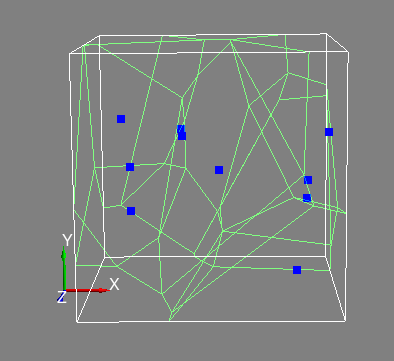

Therefore, recrystallization in rolled coarse-grained samples does not imitate the situation in rolled single crystals. However, the formation of the recrystallization texture in the same coarse-grained sample includes the growth of nuclei at grain boundaries, resulting in this process moving outside of separate grains and its control via the orientations of neighbouring grains. Assumptions were made that each system has the same critical stress and that σ RD = σ TD.ĭevelopment of the rolling texture in α-Zr single crystals was studied as applied to coarse-grained samples, since lattice reorientation in separate coarse grains as a first approximation occurs independently of similar processes in other grains. Calculated systems are characterized by the largest values of the Schmidt factor. Regions of stereographic projection for the α-Zr sample, whereby its rolling, different deformation systems operate depending on the orientation of the grain basal axis. This indicates that in polycrystalline α-Zr, the rolling texture develops mainly by means of basal, pyramidal and prismatic slip.

4) are finally directed to the maxima of rolling textures T1 or T2. The continuous arrows coinciding with experimentally observed reorientation trajectories through the slip of basal axes ( Fig. 1, thereby moving basal axes further to the centre of stereographic projection. Among such results is the obtaining of quasi-monocrystalline foils by the cold rolling of BCC single crystals (Mo, Nb) in the case of initial orientation, revealed experimentally, throws them into the neighbouring region of the basal slip shown in the diagram in Fig. In the rolled single crystal, these regions originate from the same monocrystalline matrix, due to the inevitable non-uniformity of plastic deformation therefore, they are separated from neighbours by low-angular boundaries, except for the case of twinning, which was most often observed in the current work.Įxperiments involving the rolling of single crystals can provide results that may be unreachable by similar experiments with polycrystals. In the polycrystal, these regions correspond to individual grains and are separated from neighbours by high-angular boundaries.

A rolled polycrystal is a conglomerate of rolled single crystals, but a rolled single crystal differs from a polycrystal (or a rolled polycrystal) in terms of boundary characteristics, which separate regions with different orientations. The single crystal, subjected to plastic deformation (most often one deals with rolled single crystals) does not become a polycrystal at the same time, it ceases to be a single crystal, because of the crystallographic texture that forms in it due to the number of initial orientations of this single crystal. In principle, concepts of 'polycrystal' and 'single crystal' ought to be associated with the concept of that of 'deformed single crystal'.

When considering the plastic deformation of single crystals, the experimental analysis of their ensuing recrystallization becomes simpler: in the grains of a polycrystal, plastic deformation creates a wide spectrum of substructures depending on the crystallographic orientation of grains, whereas in the case of a deformed single crystal, initial substructure conditions are much more limited. The latter entails numerous processes such as recovery, growth of recrystallization nuclei and the competition of new grains. Recrystallization of metal material is a complicated phenomenon that unites different aspects of its profile, including plastic deformation, strain hardening and behaviour by heat treatment.

0 kommentar(er)

0 kommentar(er)